CCTV News:In recent years, China’s new energy vehicle market has experienced explosive growth, and a round of "retirement tide" of new energy batteries is also coming. The battery contains a variety of heavy metals, which will cause environmental harm if it is not handled properly. While the new energy automobile industry is booming, where should the retired batteries go?

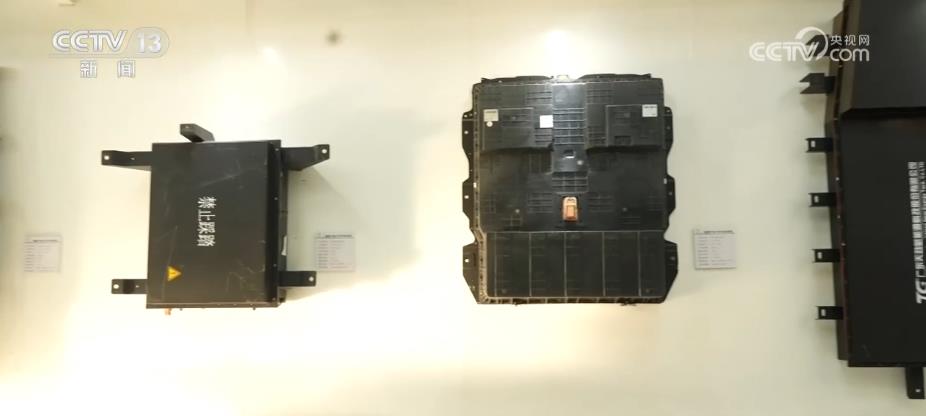

In a battery recycling plant in Guangdong, the reporter saw that the batteries retired from new energy vehicles were piled up in the whole factory.

Lin Xiaojie told reporters that in order to deal with the surge of retired batteries, the company built two new factories in Jiangmen and Jiangsu in 2023, and opened 10 new production lines. After the retired batteries enter the factory, they will go through the processes of screening, crushing and smelting. Valuable metals such as nickel, cobalt and manganese are extracted and resold. However, if this process is not handled properly, it will cause pollution to the environment.

According to statistics, China has entered a period of large-scale decommissioning of power batteries. In 2023, China’s decommissioned power batteries will reach 590,000 tons. Since 2028, the decommissioning of power batteries in China will exceed 2.6 million tons per year. What should I do with the surge in retired batteries? The reporter saw various solutions in the investigation.

According to the national standard for new energy vehicles, the remaining 80% capacity of the power battery can be retired. The decreased battery capacity will reduce the cruising range and affect the user’s experience. However, retired batteries can still be used in energy storage, electric bicycles and other scenes with low requirements on battery performance to achieve "step utilization".

The "chain" on the data is the "health account" of the battery book.

Although "step-by-step utilization" can prolong the service life of power batteries, it is not easy for recycling enterprises to practice, mainly because the cost of knowing the loss degree of retired batteries is very high. The reporter found in the investigation that the application of a new technology is bringing changes to the industry.

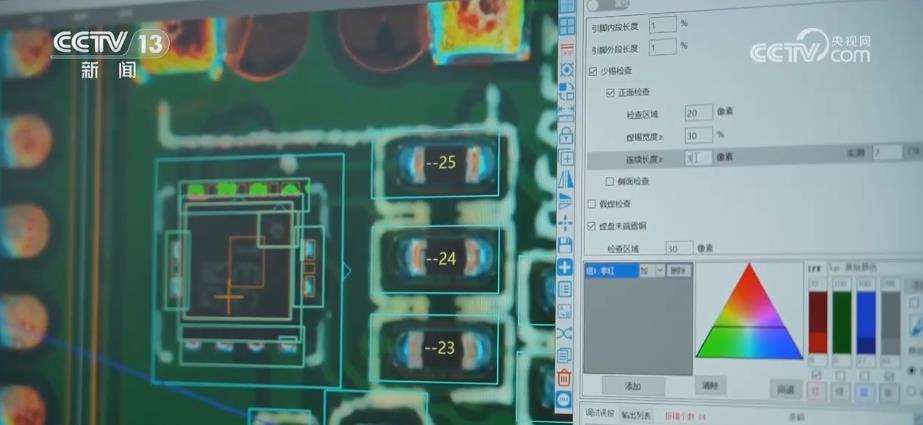

In front of this big screen, the health data of more than 30 thousand power batteries are flashing in real time. Don’t underestimate these data. Liao Zhicheng, the head of the battery operation company, told reporters that they can make some batteries sell for three times more when they are recycled.

In the past, if you want to reuse the retired batteries, the recycler can only disassemble the battery pack, test the health of each battery cell, pick out the appropriate ones and assemble them into new battery packs. And more recycling enterprises that lack the corresponding technology and manpower can only dismantle and crush the retired batteries as waste products and sell the heavy metals in the batteries directly.

The chip in Liao Zhicheng’s hand is like a "healthy housekeeper" on the battery. It not only "accounts" the use of the battery at all times, but also uploads the data to the blockchain platform in real time so that they cannot be tampered with. In this way, the recycler can know all the "health data" of the battery without disassembling them one by one. The reporter learned that battery packs with a high degree of "health" can be sold to 300 yuan at the time of recycling, which is three times that of the past.

At present, China has built the world’s largest new energy equipment blockchain platform, with more than 8 million new energy equipment on the chain. With the use of street lamps, toys and other scenes that require less battery capacity to join the cycle, it is possible to use new energy batteries more times.

Green cycle of new energy batteries from production to recycling.

After retirement, the service life of new energy batteries will become longer, but they will eventually be dismantled and recycled. How to make the new energy battery form a green cycle of energy saving and environmental protection from production to recycling?

China’s lithium resources account for only 7% of the world’s total, but China’s production and sales of electric vehicles account for 60% of the world’s total. Therefore, it is of great significance to extract lithium, cobalt, nickel and other metals from batteries and recycle them into new batteries.

The reporter learned in the investigation that at present, more than half of the retired batteries are handled by enterprises that do not have the qualification to handle them. There are some problems in dismantling and recycling, such as high energy consumption, low metal recovery rate and poor environmental protection. In view of the present situation, the Ministry of Industry and Information Technology announced four batches of white list enterprises for power battery recycling, and actively guided the regularization of power battery recycling.

Experts told reporters that to form a stable, green and sustainable recycling system for power batteries, unified national standards, industry standards, recycling standards and recycling channels are needed. In recent years, China has successively issued national standards such as power battery disassembly specifications and residual energy detection, so as to promote the national unified coding of power batteries. The relevant departments said that they are speeding up the formulation of the Management Measures for the Recycling of Power Batteries for New Energy Vehicles to further improve the standard system of power batteries.